Heavy duty build machines for verge and field mowing, ‘S’ version for extra heavy duty applications with larger diameter rotor (200mm diameter/8″) and greater hood clearance than standard MUC (150mm/6″ diameter rotor).

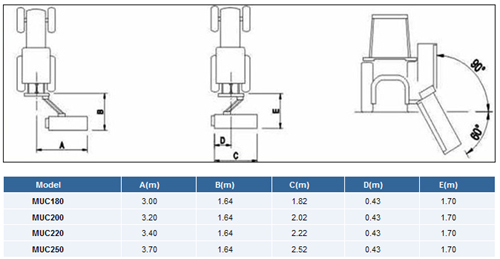

FOUR modes of operation;

- Standard in-line flail mower

- Fully offset verge mower (left hand standard, right hand option)

- To -60° angle ditch mower

- To +90° angle bank and hedge mower

Standard specification includes;

- Hydraulic offset with relief valve security system

- Hydraulic angling of mowing head

- Outboard mounted gearbox to allow full cutting width outside tractor wheels

- 3 postition opening rear door

- Double skin

- Fully floating head

- Two rows of counter blades for shredding cut material

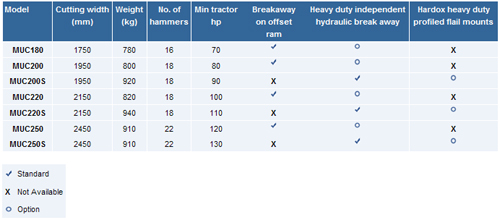

Wide range of models

- Standard or heavy duty build for 70-200hp tractors.

- Cutting widths 1.6/1.8m/2.0m/2.2m/2.5m

- Standard cast hammer flail or optional back to back grass flail.

- Heavy duy 150mm (6″) diameter flail rotor

- Optional ‘S’ version with 200mm (8″) diameter rotor and greater hood clearance for the toughest environments.

Heavy duty ‘S’ build option for extra versatility

The heavier build ‘S’ models are fitted with a larger (200mm) diameter flail rotor and have greater clearance between the flail rotor and machine frame for easier passage of material in long or very heavy mowing conditions. These machines are also more suitable for heavy use situations or in woodland and municipal areas where obstructions such as tree stumps may be encountered.

Fully floating

3 point hitch on all models and fixed/floating positions of the head levelling ram allow the Multi-Use’s heavy duty mowing head to self-level on its own roller. This enables the mower to follow the ground contours and keep a uniform cutting height. These systems also remove stress from the mower linkage and frame during operation. Grease points on all linkage pivots allow for easy maintenance and trouble free operation. Adjustable compression springs control the break back system which prevents damage if the mowing head hits an obstruction. The rear roller and rotor benefit from internally mounted bearings with double seal protection.

Tractor requirements:

540 rpm PTO shaft

2 x double acting spool valves, 1 for hydraulic offset, 1 for inclination of head

Options:

Double acting spool valve with cable control

Hardox profiled flail mounts

Flails:

Heavy duty cast hammer flail as standard

Can be interchanged with heavy duty back to back Y flail